Kurt J. Lesker ALD150LX

Film Sense In Situ Ellipsometer Integration

See our latest paper, which used a Film Sense FS-8 in situ ellipsometer, integrated with a Kurt Lesker ALD150LX system, to characterize the ScN GPC vs. process conditions: Ultrahigh purity plasma-enhanced atomic layer deposition and electrical properties of epitaxial scandium nitride

The relationship between Film Sense and Kurt J. Lesker began near the inception of Film Sense

In fact, the first Film Sense FS-1 in-situ testing was performed on a Kurt J. Lesker ALD150LX reactor in 2014. The FS-1 has since been integrated on multiple Lesker ALD reactors, and has been used to characterize a wide variety of thin films including: Al2O3, TiO2, HfO2, and TiN.

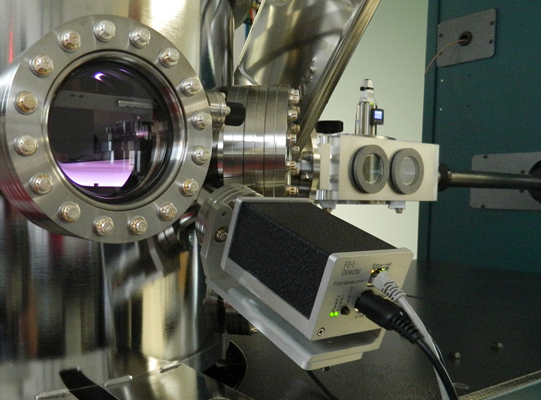

The ALD150LX was designed from the ground up for advanced R&D and features remote plasma as well as in-situ ellipsometry as a primary means of real time process monitoring and control during ALD. Patented Precursor Focusing TechnologyTM (PFTTM) prevents unwanted film deposition on sensitive surfaces inside the reactor including the analytical port windows used for light transmission during in-situ ellipsometry. The layout of the plasma-enhanced ALD (PEALD) reactor makes installation and operation of the compact FS-1 unit simple and easy.

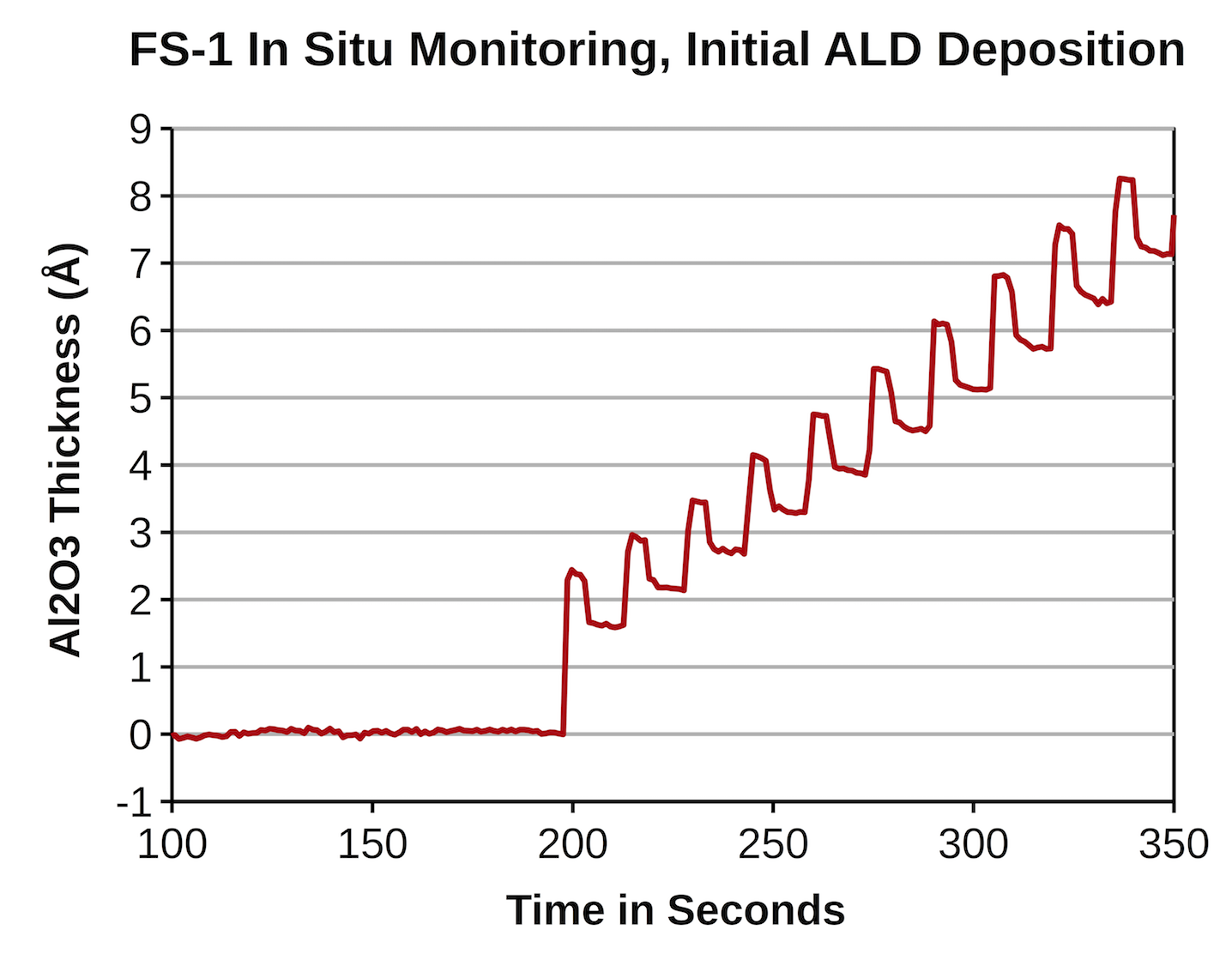

The Film Sense vision “to create easy-to-use and affordable ellipsometers” is especially relevant for in-situ applications. The Film Sense FS-1 realizes this vision by providing the power of Multi-Wavelength Ellipsometry, at an affordable price and compact size that is ideal for in-situ measurements. The FS-1 can provide real time thickness data with exceptional precision, which can be indispensable for the efficient development of new ALD processes. In the plot below, the “steps” in the data are direct observations of the thickness changes on the sample throughout the ALD cycles: the thickness increases and saturates as the precursor is introduced (trimethyl aluminum in this case), and then decreases as the film is oxidized (thermally by H2O in this case).

To learn more about the Lesker ALD150LX reactor contact Noel O’Toole or visit the Lesker website.

“Overall performance, affordability and ease of use has made the FS-1 a workhorse for our ALD process as well as equipment development efforts. The next generation FS-1EX provides a combination of higher beam intensity and wider spectral range improving both precision and accuracy. For metallic thin films such as TiN, Pt and Ru, two additional IR wavelengths enhance the ability to monitor film thickness and resistivity in-situ during growth. This enhanced performance helps us to streamline development efforts by effectively understanding the impact of different process conditions on film quality in real-time.”

Bruce Rayner – Principal Scientist

Atomic Layer Deposition, Kurt J. Lesker Company

Film Sense In Situ Application Examples

The FS-1 has been installed for in situ measurements on many different ALD reactors, including custom designs, and commercial reactors from the companies below.