Products

Multi-Wavelength Ellipsometers for Thin Film Measurements

Multi-Wavelength Ellipsometer

The 4th generation Film Sense Multi-Wavelength Ellipsometer systems are now available, with more wavelengths and wider spectral range!

Automated Mapping Systems

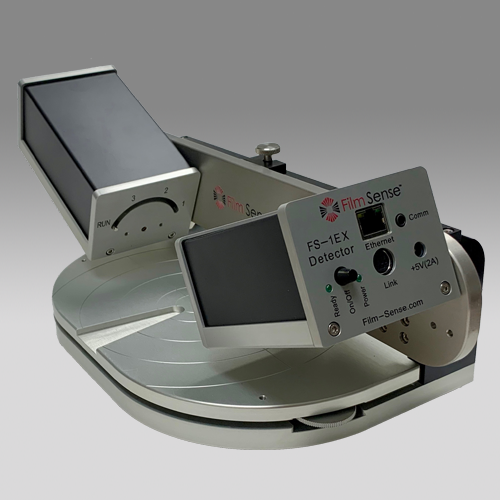

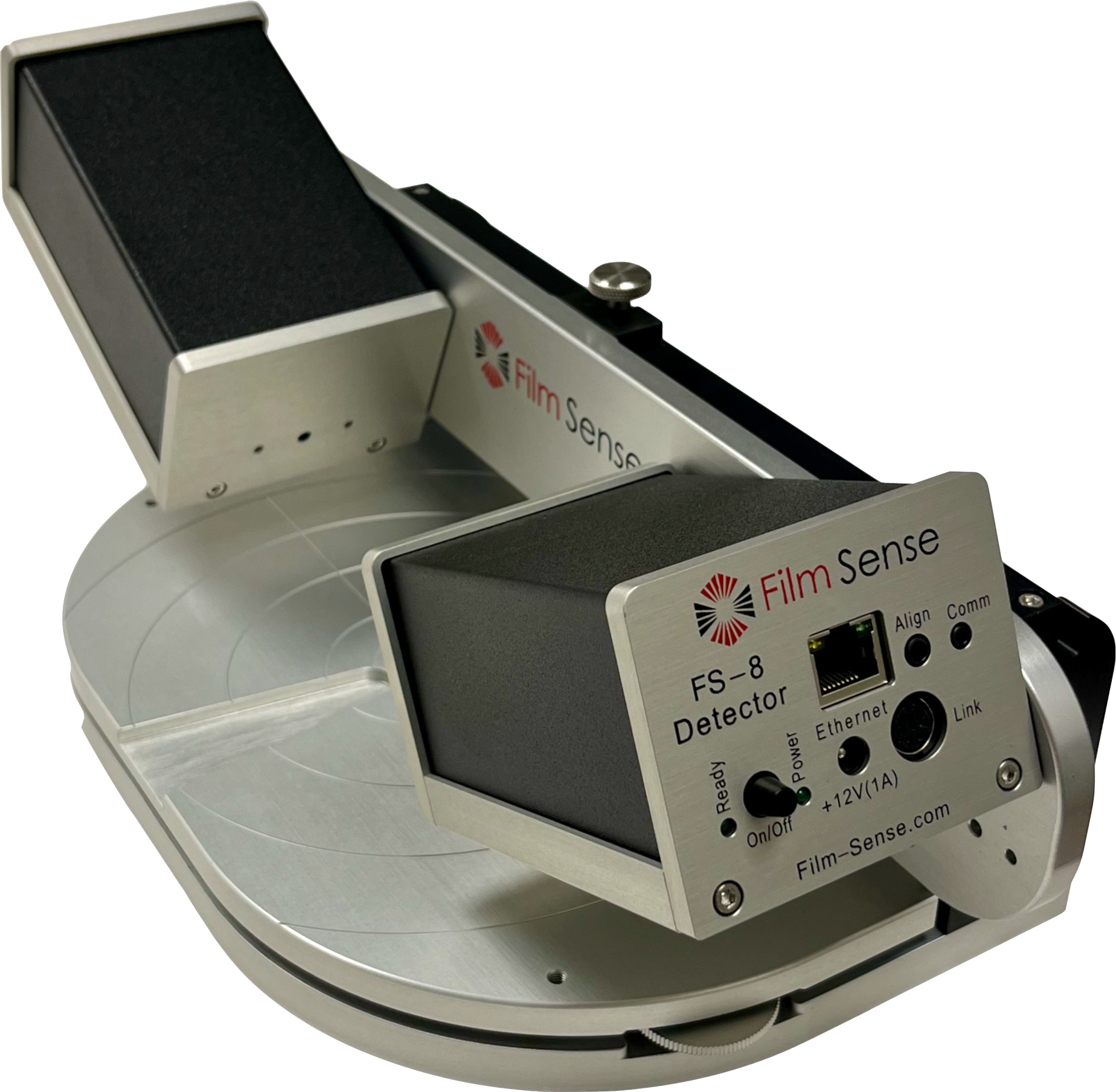

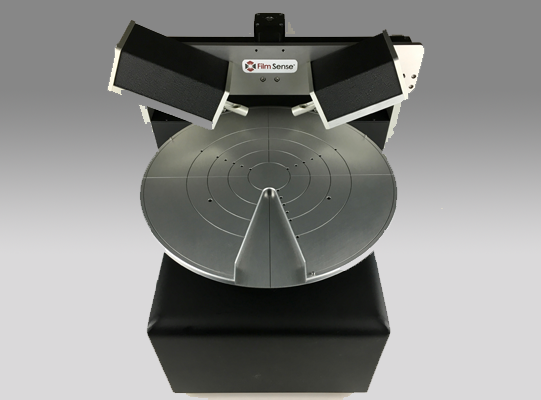

The FS-RT300 combines an FS-8 Multi-Wavelength Ellipsometer with a compact automated mapping stage to provide fast, accurate, and reliable film thickness uniformity measurements across a wafer.

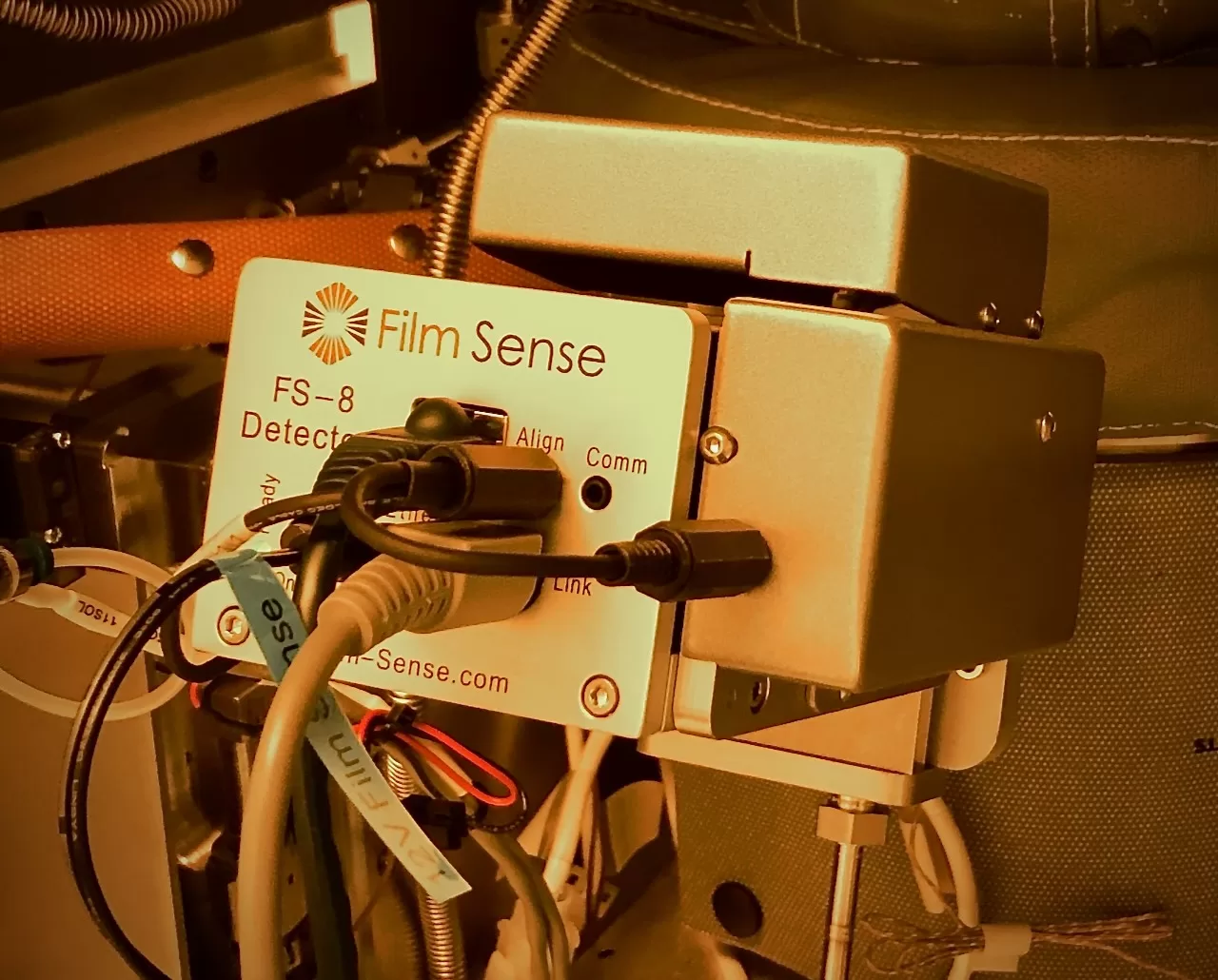

In Situ Monitoring

Film Sense Multi-Wavelength Ellipsometers are ideal for in situ realtime monitoring and control of thin film deposition and etching processes.

Film Sense

Innovative Technology

Key Features and Benefits of all Film Sense Multi-Wavelength Ellipsometers

Features |

Benefits |

| Multiple LED sources (either 4 or 8, with wavelengths ranging from 370 – 950 nm, depending on the system) | Long lifetimes (>50,000 hours), with no costly lamp changes, time consuming alignments or PM procedures |

| No moving parts in the ellipsometric detector* | Fast measurement times (ellipsometric data in 1.7 ms, with the new Fast Mode feature) and long term reliability |

| Excellent thickness precision, better than 0.0004 nm for many samples (for a 1 second acquisition), even for sub-monolayer film thicknesses | Measurement precision that is only possible with an ellipsometer |

| Integrated computer for instrument control and data analysis, with a web browser interface accessible from any modern computer, laptop, or tablet | No complicated software setup and maintenance |

|

Completely self-contained system |

No external electronics box or fiber connections |

* US Patent #9,354,118

Operation & Features

Multi-Wavelength Ellipsometer

FS-XY150

Automated Mapping

System

Testimonials

“These FS-1 ellipsometers are one of the best upgrades to our atomic layer processing reactors, and have now become an integral part of all our experiments on ALD and ALE.”

Dr. Sumit Agarwal – Colorado School of Mines

“The Film Sense FS-1 in situ ellipsometer has greatly facilitated data acquisition and understanding of the thin film deposition processes in our lab. The instrument was relatively easy to incorporate onto a vacuum chamber, and includes a user-friendly manual and tutorial to explain basic operation. With this tool, we are able to collect much more information during a deposition, including measurements between ALD half-cycles that are not feasible with ex situ techniques. These ellipsometers have become an integral part of our laboratory research, and we look forward to continuing to work with Film Sense in the future.”

Rachel Nye, PhD – student in Chemical Engineering

Parsons Research Group, North Carolina State University

“Overall performance, affordability and ease of use has made the FS-1 a workhorse for our ALD process as well as equipment development efforts. The next generation FS-1EX provides a combination of higher beam intensity and wider spectral range improving both precision and accuracy. For metallic thin films such as TiN, Pt and Ru, two additional IR wavelengths enhance the ability to monitor film thickness and resistivity in-situ during growth. This enhanced performance helps us to streamline development efforts by effectively understanding the impact of different process conditions on film quality in real-time.”

Bruce Rayner – Principal Scientist

Atomic Layer Deposition, Kurt J. Lesker Company

“The FS-1 is an excellent basic ellipsometer. Reliable, easy to use, low maintenance, and great value for money. Films Sense have been great at helping us characterize our thin films, and get accurate measurements. Fully recommended. ”

Dr Ruy Sebastian Bonilla – Research Fellow

Oxford Materials Department

“We have purchased four Film Sense products for our small R&D group. We have three FS-1 units and one FS-1EX unit with the RT300 mapping stage. The Film Sense software is the most intuitive and easiest to use of all the ellipsometers I have experience using. Our favorite feature is the multi-sample analysis method. This feature allows you to determine the optical constants for new or poorly fitting films by simply measuring a small number of samples with various thicknesses. Having knowledge of the actual thickness values is not even necessary. The software understands the optical constants must be the same for all samples, and each sample varies only in thickness. The user just needs to collect the data and press the fit button. New films layers are created in just a couple of minutes. We also love the automatic adjustment for sample height on the RT300 mapping stage. Our process engineers are constantly adjusting the height on competitor’s units without this automatic feature.”

-Staff Systems Engineer at large semiconductor OEM

“The Film Sense FS-1 is a powerful and reliable tool for in-situ characterization of ALD films. The real-time dynamic thickness measurements were critical to understanding the growth characteristics of multicomponent oxides, such as lead zirconate-titanate (PZT), which I studied for my dissertation research through the University of Maryland. The in-situ thickness data I collected with the FS-1 allowed me to screen precursors much more quickly than if I had to rely on ex-situ characterization methods. I continuously used the FS-1 for over five years and haven’t experienced any downtime other than during occasional realignments when switching from ex-situ to in-situ measurement modes. The FS-1 would make a valuable addition to any laboratory looking to enhance their nondestructive thin-film thickness measurement capability.”

– Nicholas A Strnad, Ph. D.